HPTE – High-pressure torsional extrusion

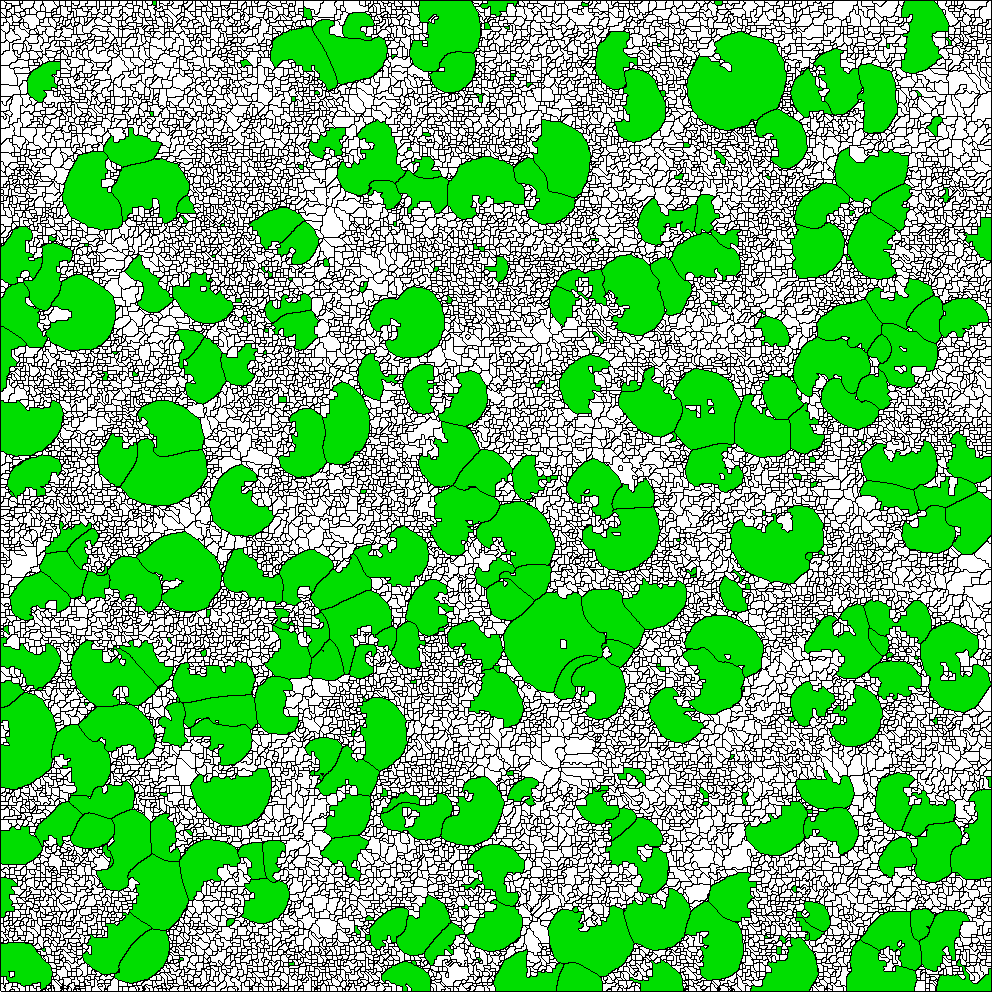

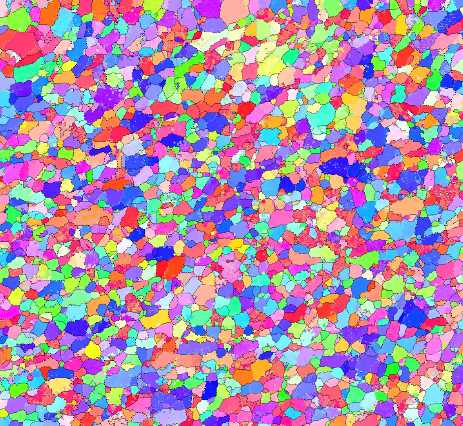

The high-pressure torsion extrusion (HPTE) process was established at the INT for the production of novel ultrafine-grained to nanocrystalline materials with enhanced mechanical properties. Using the HTPE process it is possible to produce ultrafine-grained morphologies with a very high dislocation density through high shear deformations of the material in the active zone. The main advantages of this method are: (I) Long rods can be processed directly. (II) The process can be seamlessly integrated into a technological chain. In addition, the presence of a strong velocity gradient in the sample cross-section during the HPTE process offers the possibility to design hybrid materials or composite parts with a spiral architecture of functional elements for specific applications. After the HPTE process, the material can be heat treated to achieve the desired ductility by recrystallization annealing. The aim of this combined experimental and simulative project is to develop a profound knowledge about critical process parameters in order to precisely optimize the material properties. In the first step, the material is experimentally analyzed before and after the heat treatment to build up a reference database. A mesoscopic multiphase-field model is calibrated with the help of the gained experimental results and simulations are performed to systematically allow variations of the involved process parameters. Orientation microscopy measurements of the material microstructure before annealing serve as simulation input. In the second step, this methodology is extended to the deformation process.

| Julia Ivanisenko | Institute of Nanotechnology (INT) |

| Daniel Schneider | Institute for Applied Materials - Computational Materials Science (IAM-CMS) |

| Michael Selzer | Institute for Applied Materials - Computational Materials Science (IAM-CMS) |

| Brigitte Baretzky | Institute of Nanotechnology (INT) |

| Britta Nestler | Institute for Applied Materials - Computational Materials Science (IAM-CMS) |