Design of “self-assembled” devices in printed electronics: Modeling and experimental investigation of wetting phenomena for multi-component and multi-phase fluids on patterned substrates

In printed electronics, the performance of devices is highly linked to the printing accuracy and governed by the overlap of non-conducting layers with the conducting metallic electrodes. To improve the printing accuracy and to reduce the parasitic effects engendering from the overlapping layers, the substrate can be pre-structured in such a way that superhydrophobic and superhydrophilic areas are deliberately designed on the substrate. The difference in the wettability between the patterned areas leads to a controlled spread of the ink solution, increasing the printing precision and removing the parasitic effects. On these pre-structured substrates, various kinds of inks containing different materials (conductor, semiconductor, and dielectrics/ion gels) are printed, in order to select compatible materials for the pre-structuring process. The present project aims to accelerate the design of devices for printed electronics by scrutinizing the wetting behavior of the printing fluids on patterned substrates via high performance simulations (3D+t) supported by experiments as the real part of the digital twin.

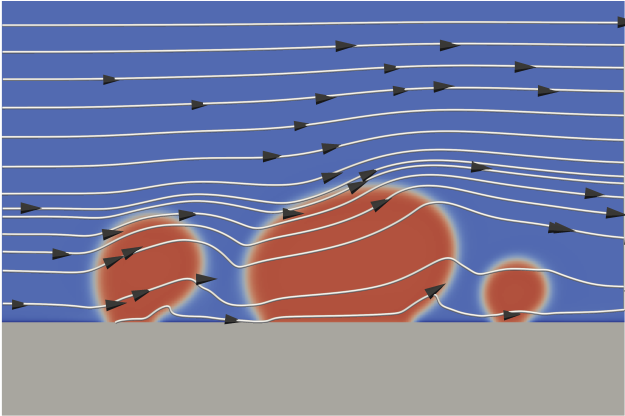

The wettability of the ink solutions on the pre-structured substrates is studied within the framework of the phase-field method, which has been developed and successfully applied in previous Virtual Materials Design project. The current project considers ink solutions containing more than one component. Thus, it is necessary to develop a phase-field model for simulating the wetting behavior of multi-component and multi-phase liquids on solid patterned substrates. For such a consideration, the ink solution spreads on the pre-structured substrate, which may lead to an inhomogeneous distribution of the constituting components, such as electrolyte/dielectric, semiconductor, and conductors, on the patterned substrate. An understanding of the underlying mechanism is essential for inhibiting the inhomogeneous layout and thus to achieve a more homogeneous deposition of the target printing fluids on the desired area of the substrate.

The results from the phase-field simulations of the wetting behavior for the ink-jet solutions are compared with experiments. The printed substrates are characterized through conductivity measurements, microscope images, and SEM images.

| Name | Institute |

|---|---|

| Britta Nestler | Institute for Applied Materials - Computational Materials Science (IAM-CMS) |

| Jasmin Aghassi | Institute of Nanotechnology (INT) |